Home > Campaigns > Plastic Pollution & Climate > Hidden Hazards: The Chemical Footprint of a Plastic Bottle

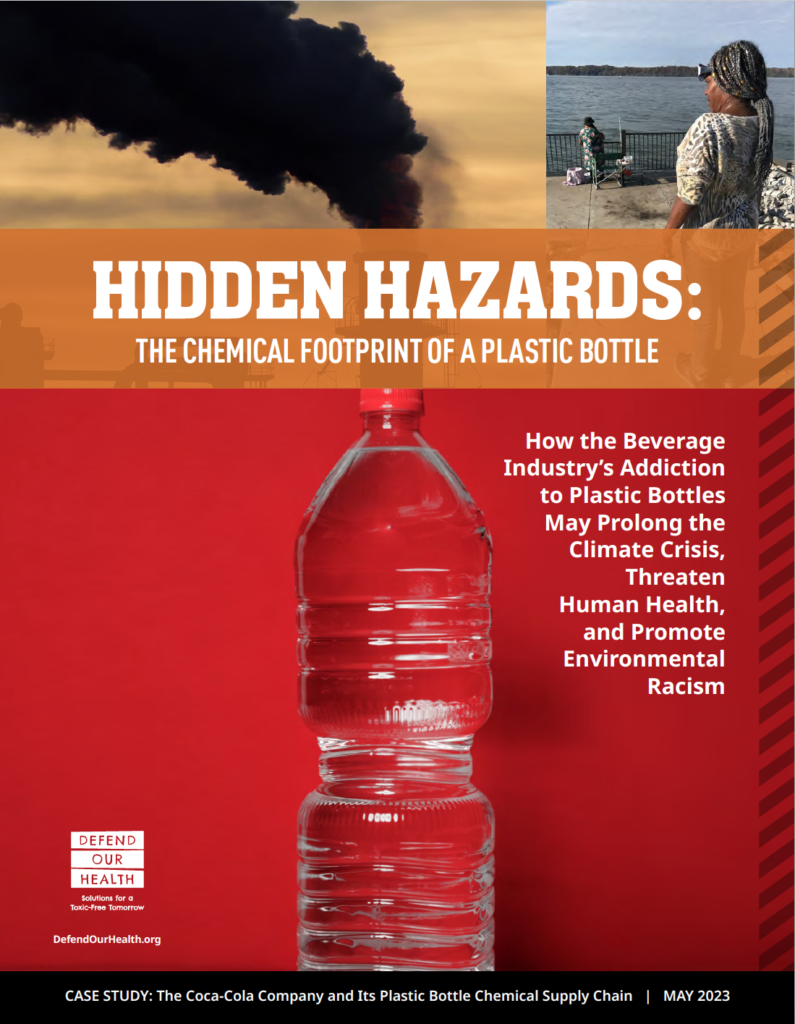

Hidden Hazards: The Chemical Footprint of a Plastic Bottle

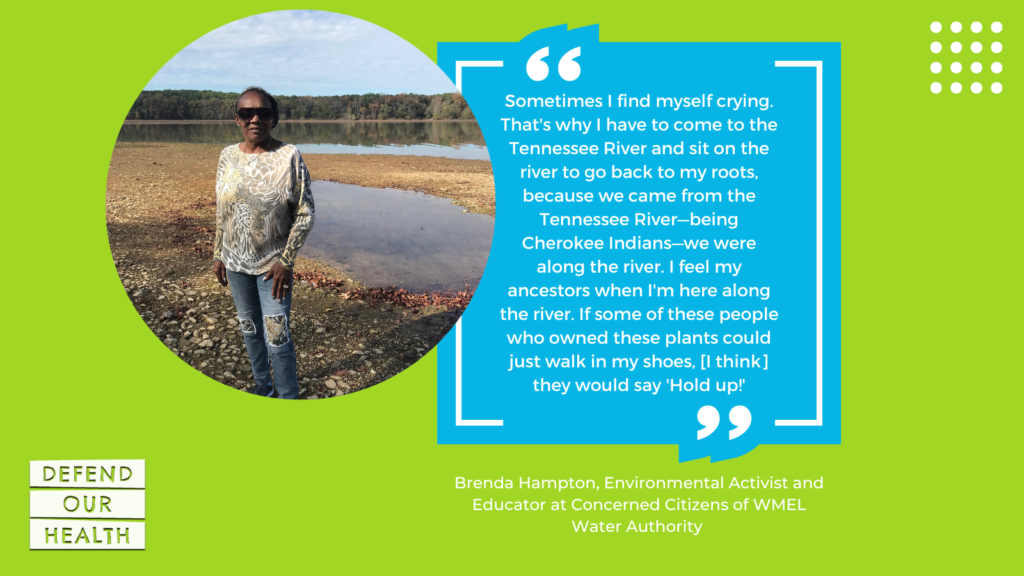

Worldwide, the beverage industry buys more than 500 billion plastic bottles every year to package its products. This insatiable demand for plastic bottles drives the production of a common plastic known as polyethylene terephthalate or PET. Plastic bottles consume a quarter of all PET plastic production worldwide. A first-ever study, Hidden Hazards: The Chemical Footprint of a Plastic Bottle, reveals the potential threats to human health, environmental justice, and climate change created by the chemical manufacturing and plastics production processes required to turn crude oil and fossil gas into plastic bottles, as well as from consumption of plastic-bottled beverages and final disposal of the bottles. All along the plastic bottle supply chain, these burdens fall heaviest on communities of color and low-income communities. The report urges Coca-Cola and other beverage companies to take immediate action to require suppliers to replace antimony and cobalt in plastic bottles with safer alternatives and to achieve zero discharge of cancer-causing chemicals to the air and water along its supply chain. By 2030, these companies should replace 50% of plastic bottles with reusable and refillable container systems and end the use of virgin fossil-based PET plastic by 2040 to help solve the climate crisis and minimize toxic burdens.

Read the full report: here.

Read the executive summary: here.

Read the press release: here.

Key Figures:

Figure 1: The Chemical Footprint of a Plastic Bottle

Figure 2: Where do PET Plastic Bottles Go After a Single Use in the US?

Figure 3: Demographics of PET Supply Chain Fence-line Communities

Figure 4: The Coca-Cola Company’s US Chemical Supply Chain

Table 2: The PET Plastic Industry is a Top Industrial Polluter of 1,4-Dioxane in the US

Table 3: Chemical Suppliers for PET Plastics Are Top Polluters of Ethylene Oxide in the US

Map: Locations Associated with PET Plastic Manufacture in the US

Table of Contents:

Executive Summary

Introduction

End of Life: Plastic Bottle Waste

On the Shelf: Plastic-Bottled Beverages

Plastic Resin: Polyethylene Terephthalate

Petrochemical Building Block: Terephthalic Acid

Primary Petrochemical: Ethylene

Primary Petrochemical: Para-Xylene

Nonrenewable Resource: Natural Gas

Nonrenewable Resource: Crude Oil

Accounting for the Chemical Footprint of a Plastic Bottle

Conclusions and Recommendations

Notes and References

Appendices

Take Action Today

Tell Coca-Cola execs to get rid of any toxic plastic bottles